Inter Pipeline’s Heartland business is committed to setting a new standard in customer service, reliability and responsible operations. Heartland leverages value-added opportunities for Alberta’s abundant supply of natural raw resources to diversify the local economy, create job opportunities, invest in the community and capitalize on key geographic advantages. This business is currently comprised of Heartland Polymers.

Heartland

North America’s only single-site propane dehydrogenation and polypropylene complex

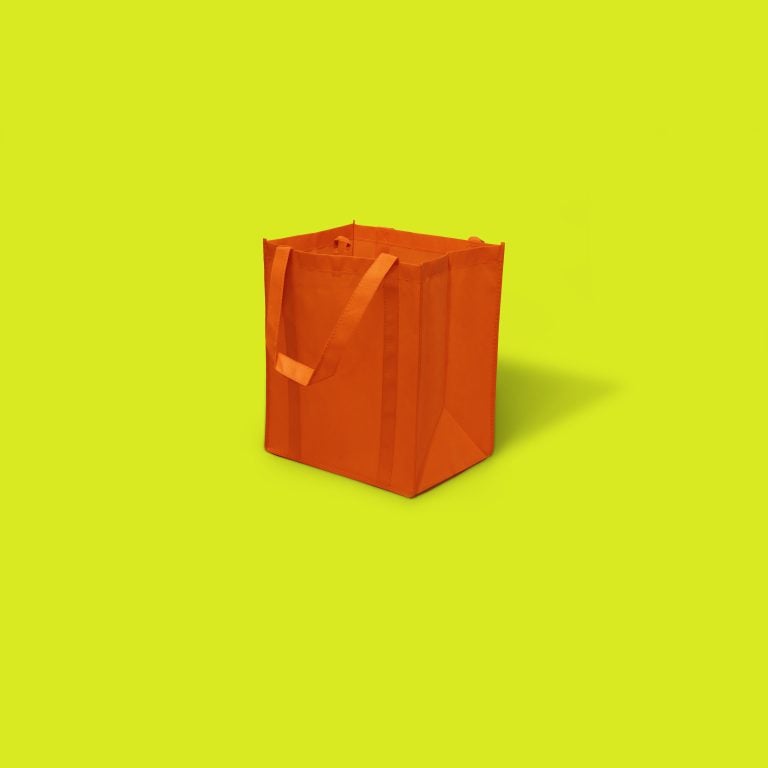

Heartland Polymers is leveraging Western Canada’s abundant supply of local propane to produce polypropylene (PP), a high value plastic that can be recycled which global manufacturers transform into everyday products out of the Heartland Petrochemical Complex (HPC), our one-of-a-kind operation.

Located in Central Alberta, the world-scale integrated complex is comprised of North America’s only single site propane dehydrogenation (PDH) plant and polypropylene (PP) plant and a co-generation central utilities block (CUB). Heartland is producing high quality products while continuing to partner on innovations to reduce waste and increase recycling. Heartland Polymers has a nameplate capacity of 525,000 tonnes of polypropylene per year with rail shipments leaving the facility daily. Heartland’s state-of-the-art rail loading complex (RLC) was designed for distributing quality polypropylene products delivered via extensive rail network and storage facilities, ensuring reliable delivery of product to customers across North America and the globe.

Inter Pipeline commissioned the Complex in 2022, and it entered into commercial production early in 2023. Heartland is Canada’s only PP production operation and one of the newest in the industry to produce versatile, durable, recyclable PP.

Products

Quality polymer produced sustainably, delivered reliably.

From food packaging to personal hygiene products to the parts that make vehicles safer, Heartland Polymers is delivering world-class polypropylene to help achieve a new level of sustainability in the products that shape our lives.

Currently producing homopolymers and random copolymers, Heartland Polymers are phthalate-free, meeting FDA requirements. Visit heartlandpolymers.com to find the right product for your business.

The idea was big, the opportunity, even bigger

Heartland began with a big idea. An idea for the future of Canada’s petrochemical industry, and for Alberta’s economy. Drawing on parent company Inter Pipeline’s two decades of industry experience, and after over ten years of planning and construction, this idea has moved from the drafting table to the field. We are thrilled to reach completion of this project and bring better directly to our customers.

Watch the video below to see our story take shape.

Connect with us

Get connected to Heartland Polymers today. Our team of experienced professionals is ready to answer your questions and help you discover the Heartland Polymers difference.

General Inquiries: ppsales@heartlandpolymers.com

Media Inquiries: mediarelations@heartlandpolymers.com

Heartland Polymers

Heartland Polymers is materially diversifying and strengthening Inter Pipeline’s business, while creating an attractive new market for Alberta propane.

ESG Reporting

Inter Pipeline prioritizes the safety and protection of the environment for our employees, customers, shareholders and the communities in which we operate.

Video Gallery

View our video gallery to learn more about our business, our people and our commitments.

Plastics Research in Action

Our ten-year agreement with the Northern Alberta Institute of Technology will uncover new ways to reuse and recycle plastic in Canada.

More

In 'What We Do'

Overview

Transportation

Facilities Infrastructure

Marketing

For Customers

For Suppliers